The difference between the tensile strength and yield strength

Oct 14, 2015

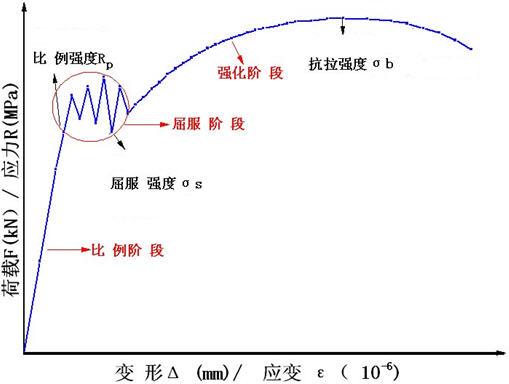

Tensile Strength: When steel yields to a certain extent, due to the rearrangement of internal grains, its ability to resist deformation increases again. Although this time the deformation has developed rapidly, but only increase when stress increase, until the stress reaches the maximum value. Since then, the ability of steel to resist deformation significantly reduced, and large plastic deformation occurs at the weakest point, where the cross section of specimen rapidly shrinking, there necking until fracture failure. The maximum stress value (b points corresponding value) before steel is broken is called the ultimate strength or tensile strength.

Yield strength: When the stress exceeds the elastic limit, the deformation increases rapidly, this time in addition to elastic deformation, but also generates portion plastic deformation. When the stress reaches point B, the plastic strain increases dramatically, the curves occurs small volatile platform, this phenomenon is called yield. Maximum and minimum stress at this stage are called the upper yield point and lower yield point. Since the value of the lower yield point is more stable, and therefore use it as material resistance index, called the yield point or yield strength.

Previous: Technical feature of rebar coupler